Application of Metal 3D Printing

Application of Metal 3D Printing

Blog Article

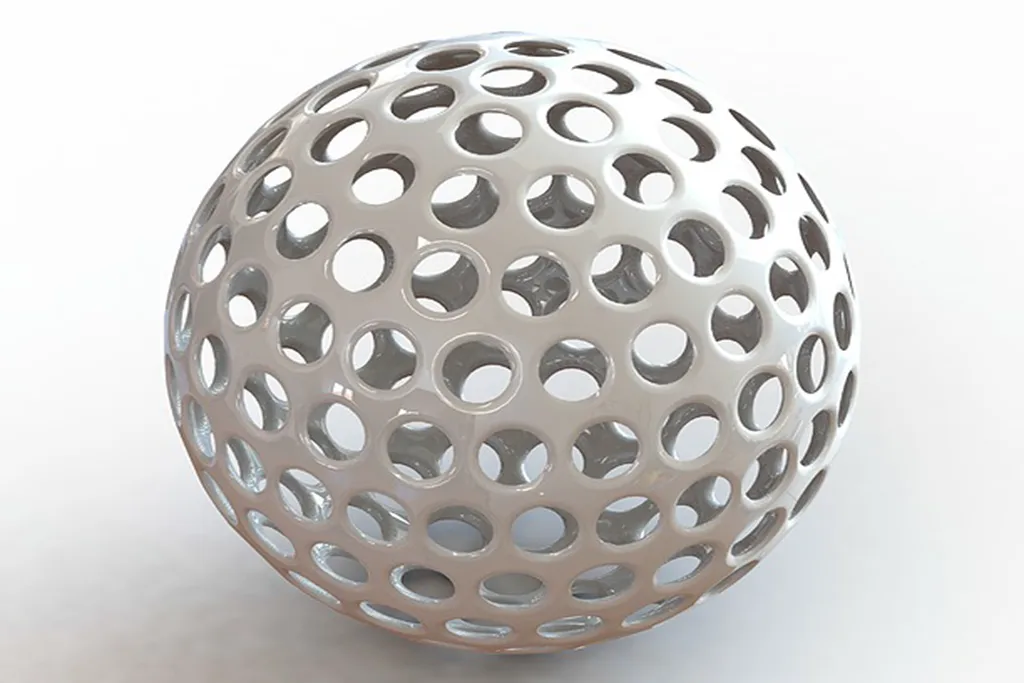

With the advancement of science and technology, metal 3D printing technology is quietly changing our manufacturing model. This advanced technology successfully transforms digital design into physical products by stacking metal powder layer by layer, injecting new innovative vitality into the manufacturing industry.

Metal 3D printing shines in the field of aerospace. Complex components that are difficult to process by traditional manufacturing methods can be easily realized through metal 3D printing technology. For example, the turbine blades in aircraft engines need to withstand high temperature and high pressure, and require complex structures and light weight. Metal 3D printing technology can finely control the microstructure and printing trajectory of metal to meet strict standards. This ability opens up new possibilities for lightweight design and performance optimization of aircraft.

The automotive manufacturing industry is also an important application field of metal 3D printing. From suspension systems to transmission systems, metal 3D printing technology can print complex automotive parts in an integrated manner, reduce the number of parts, and improve the integration and performance of the entire vehicle. In addition, the technology also supports personalized customization to meet the market’s demand for diversified and high-performance vehicles.

In the key field of medical devices, the application of metal 3D printing technology can be called a revolution in medical innovation. It can be used to create fine medical devices and implants, such as artificial joints and dental braces. These devices are carefully customized according to the patient’s individual needs, thereby improving the accuracy of the surgery and the patient’s comfort.

The advantage of metal 3D printing lies not only in its manufacturing capabilities, but also in the design freedom it brings. Designers can no longer be restricted by traditional manufacturing processes, but can boldly try new design concepts to promote product innovation.

However, metal 3D printing technology also faces some challenges, such as high cost and relatively slow printing speed. But with the continuous advancement of technology and the gradual reduction of costs, it is believed that this technology will be widely used in more fields, bringing more innovation and changes to the manufacturing industry.

Metal 3D printing technology is becoming an important part of the manufacturing industry with its unique advantages and broad application prospects. We have reason to believe that this technology will bring more surprises and convenience to our lives and work.